When it comes to structural materials, metal has become essential for its strength and versatility. However, as resilient as metal is, it’s vulnerable to elements like moisture and extreme temperatures. Metal coating methods, such as galvanizing and priming, add a protective barrier that enhances durability and lifespan, making these treatments valuable choices for many construction and industrial applications. Let’s take a closer look at two commonly used metal coating techniques: galvanized coating and priming.

Galvanized Coating

Galvanizing is one of the most effective ways to protect metal from corrosion, which is particularly crucial when the material is exposed to outdoor environments. This process involves coating the metal, typically steel, with a layer of zinc. Zinc provides excellent rust resistance, as it reacts with the atmosphere to form a protective layer of zinc carbonate. This layer acts as a barrier, shielding the underlying metal from corrosive elements, and prolongs the metal’s life, even in highly humid or coastal environments.

The galvanizing process includes dipping the metal in molten zinc, creating a bond that’s both strong and enduring. This layer serves as a “sacrificial” coating; if the surface is scratched, the zinc layer will corrode instead of the underlying metal, effectively sacrificing itself to protect the metal beneath. Galvanized coating is widely used for steel products, from construction beams to smaller items like fasteners, because of its resilience and long-term protective qualities.

For builders, contractors, and those sourcing materials, opting for galvanized metal from a trusted metal supplier ensures you’re getting a product with built-in durability, saving costs in the long run by minimizing maintenance and replacement needs. Galvanized products sourced from a reliable metal warehouse are ideal for large projects, as they guarantee a consistent quality that withstands harsh environments and heavy-duty applications.

Primed Metal

Priming is another popular coating method that adds an initial protective layer to metal surfaces. This process is often used for metals that will be further painted or coated. Priming prepares the surface to better adhere to paint or additional coatings, creating a stronger bond and making the finish more durable.

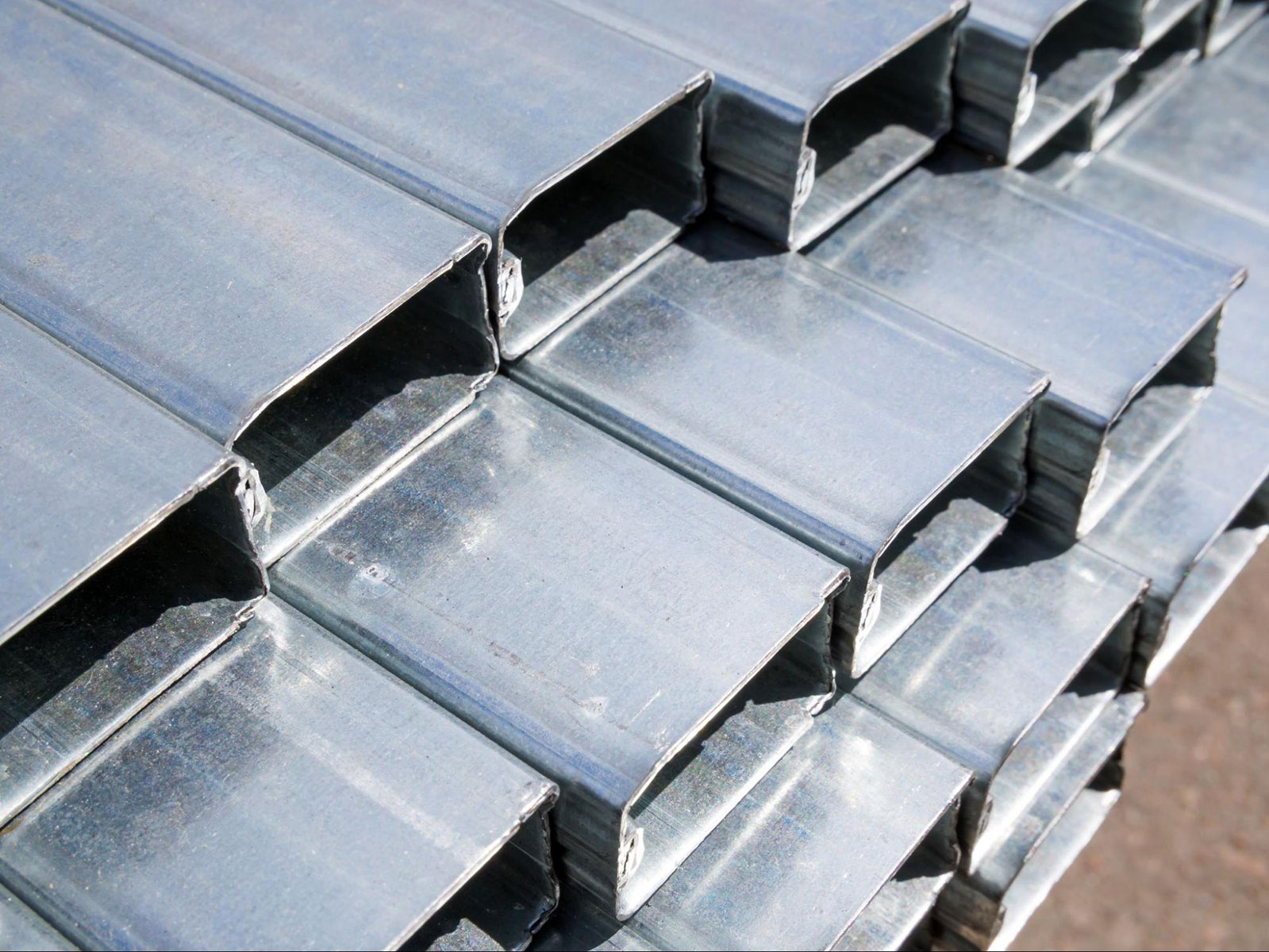

Priming is especially beneficial for structural metal pieces like cee purlins, which are often used in building frameworks. Cee purlins provide structural support to roofs and walls, requiring strength and resistance against environmental elements.

Unlike galvanized coatings, priming doesn’t necessarily provide sacrificial protection. Instead, it acts as a preliminary barrier, ensuring the paint adheres and offers additional resilience against weather and wear. For example, primed cee purlins sourced from a dependable metal provider have enhanced durability and are well-prepared for a topcoat application, making them a smart choice for projects where long-lasting performance is key.

Why Metal Coating Matters

Choosing the right coating for your metal parts or building materials is an investment in quality, durability, and longevity. Coated metal products provide additional protection against rust, corrosion, and environmental wear, giving peace of mind to builders and architects who rely on them in challenging environments.

A reputable metal supplier can ensure access to top-quality coated metals like galvanized beams or primed purlins, specifically treated to withstand harsh conditions and reduce maintenance over time. Working with a metal warehouse that stocks various coated metal products is advantageous, as it offers a range of options suitable for different applications, from construction to industrial manufacturing.

Get Your Coated Metal At General Steel Warehouse

Whether you’re working on a major construction project or a smaller-scale build, coated metal products like galvanized and primed metals are invaluable for ensuring long-lasting, reliable structures. Each type of coating brings unique benefits: galvanized metal provides robust corrosion resistance, while primed metal enhances adhesion for subsequent coatings, allowing for more customization and protection.

For those looking to source top-quality coated metal end products, General Steel offers a range of solutions tailored to meet your construction and durability needs. From structural beams to smaller components, each product is crafted with care and backed by expertise. Contact General Steel to explore a selection of coated metal products, sourced with quality and longevity in mind