Perforated metal is a material that many industries rely on thanks to its durability, flexibility, and the variety of patterns it can offer. Perforated metal is found in everything from industrial equipment to decorative panels, from construction to design. But what exactly is perforated metal, and why is it so valuable across industries?

What is Perforated Metal?

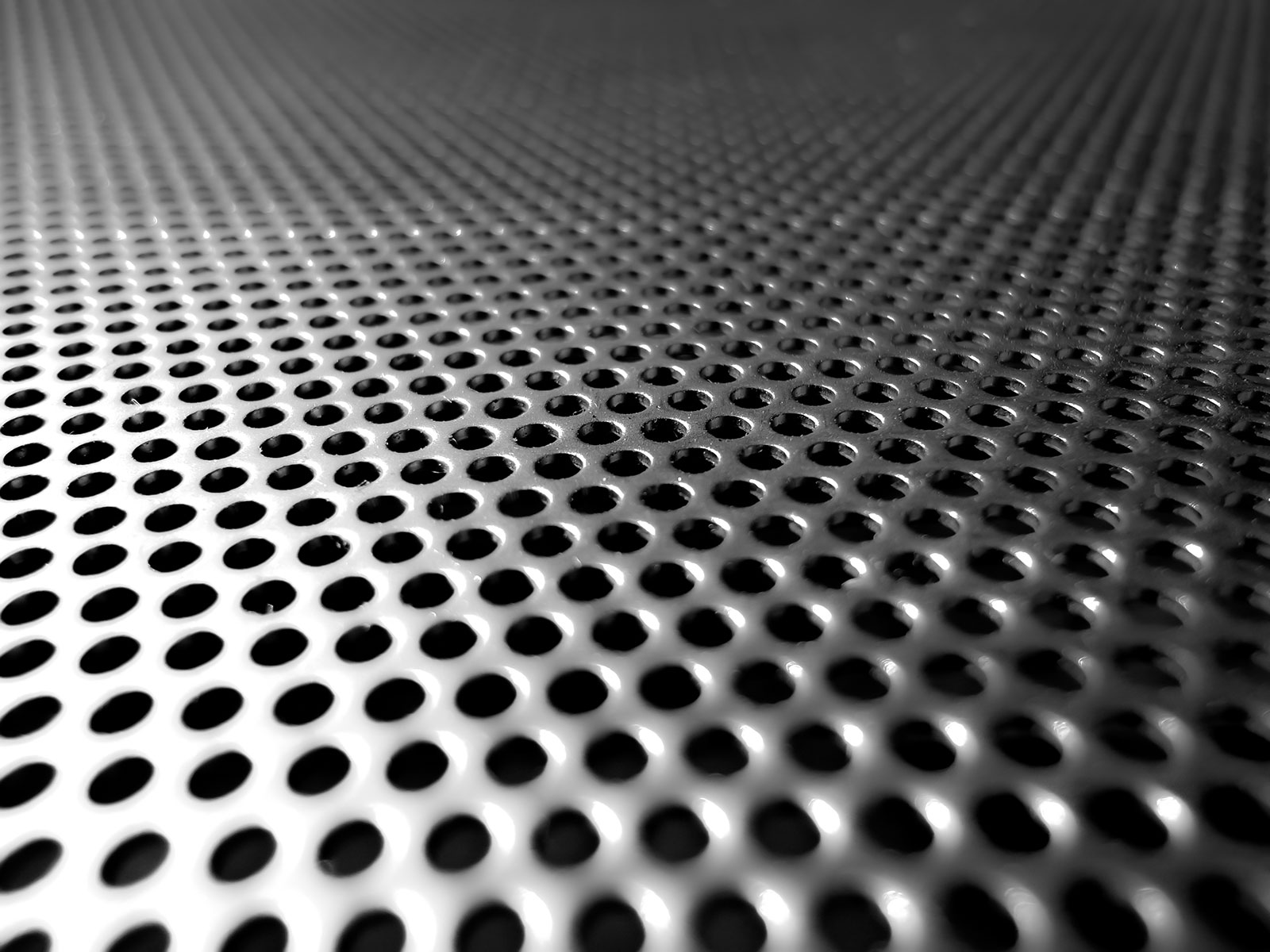

Perforated metal is a sheet of steel, aluminum, or other metal that has been punched or stamped with a series of holes, slots, or other patterns. The size, shape, and distribution of these perforations can be customized according to specific needs. The process of perforation creates a material that is both strong and lightweight, offering numerous advantages such as better airflow, improved aesthetics, and enhanced functionality.

Typically, perforated metal comes in a range of thicknesses and materials. While steel is among the most commonly used materials, aluminum and stainless steel are popular. Now that we understand what perforated metal is, let’s explore some of its most common uses.

Uses of Perforated Metal

Ventilation and Airflow

One of the primary uses of perforated metal is to improve ventilation and airflow. Because perforated sheets allow air to pass freely while providing a solid structure, they are ideal for HVAC (heating, ventilation, and air conditioning) systems.

In HVAC units, perforated metal can be used in vent covers, air ducts, and grilles. These applications enable the proper distribution of air throughout a building or space while maintaining protection from larger particles or objects that might otherwise enter the system.

Perforated metal’s balance between strength and airflow efficiency makes it an excellent choice in environments where proper air circulation is crucial—hospitals, commercial buildings, or industrial complexes. Whatever steel provider you choose, the ability to customize the perforation patterns allows for optimized airflow based on the specific design requirements.

Filtration

Filtration is another common application of perforated metal. This material can serve as a sturdy and efficient filter in agriculture and chemical processing industries. Perforated metal sheets are often used in filters to separate solids from liquids or to sift and sort aggregates like gravel, sand, or other particles.

For example, in water treatment plants, perforated metal filters can strain debris from water while allowing clean water to pass through. Similarly, in industrial food processing, perforated metal helps sort and process food products by allowing only materials of a specific size to pass through.

In mining and construction industries, perforated metal sieves or screens can be used to sort aggregates based on size, ensuring efficient processing. Sourcing from a steel warehouse or metal supplier ensures that businesses receive high-quality perforated metal tailored to these demanding applications.

Light Filtration and Privacy

In addition to functional uses like airflow and filtration, perforated metal is also commonly used for light filtration and privacy. When used in architectural settings, it can serve as sunshades, room dividers, or decorative panels. The perforations allow natural light to pass through while still providing a barrier, creating a balance between openness and privacy.

These properties make perforated metal popular in office buildings, outdoor public spaces, and even residential areas. Architects often use perforated metal as a design feature to create an interplay of light and shadow, enhancing both aesthetics and functionality.

Sound Filtering and Absorption

Perforated metal is also used in acoustic environments to help absorb sound and reduce noise pollution. It’s often used in soundproofing equipment in industrial settings, which helps dampen noise from machinery. Perforated metal panels can also be used in auditoriums and theaters to enhance sound quality by controlling how sound waves reflect off walls.

By allowing sound to pass through while absorbing excess noise, perforated metal plays a vital role in creating quieter, more controlled acoustic environments.

Explore Perforated Metal at General Steel Warehouse

From HVAC systems to filtration, light management, and sound control, perforated metal has proven itself to be an incredibly versatile material. Its durability, ease of customization, and wide range of applications make it indispensable across industries. If you’re looking for high-quality perforated metal, it’s crucial to work with a trusted Lubbock metal provider or steel warehouse that understands the unique needs of your project.

At General Steel Warehouse, we specialize in providing a wide variety of perforated metal products to meet your needs. Whether you’re looking for material for HVAC units, filtration systems, or architectural applications, our team is here to help. Contact us today to learn more about how we can serve as your go-to metal supplier and steel provider for all your perforated metal needs!